CONTACT

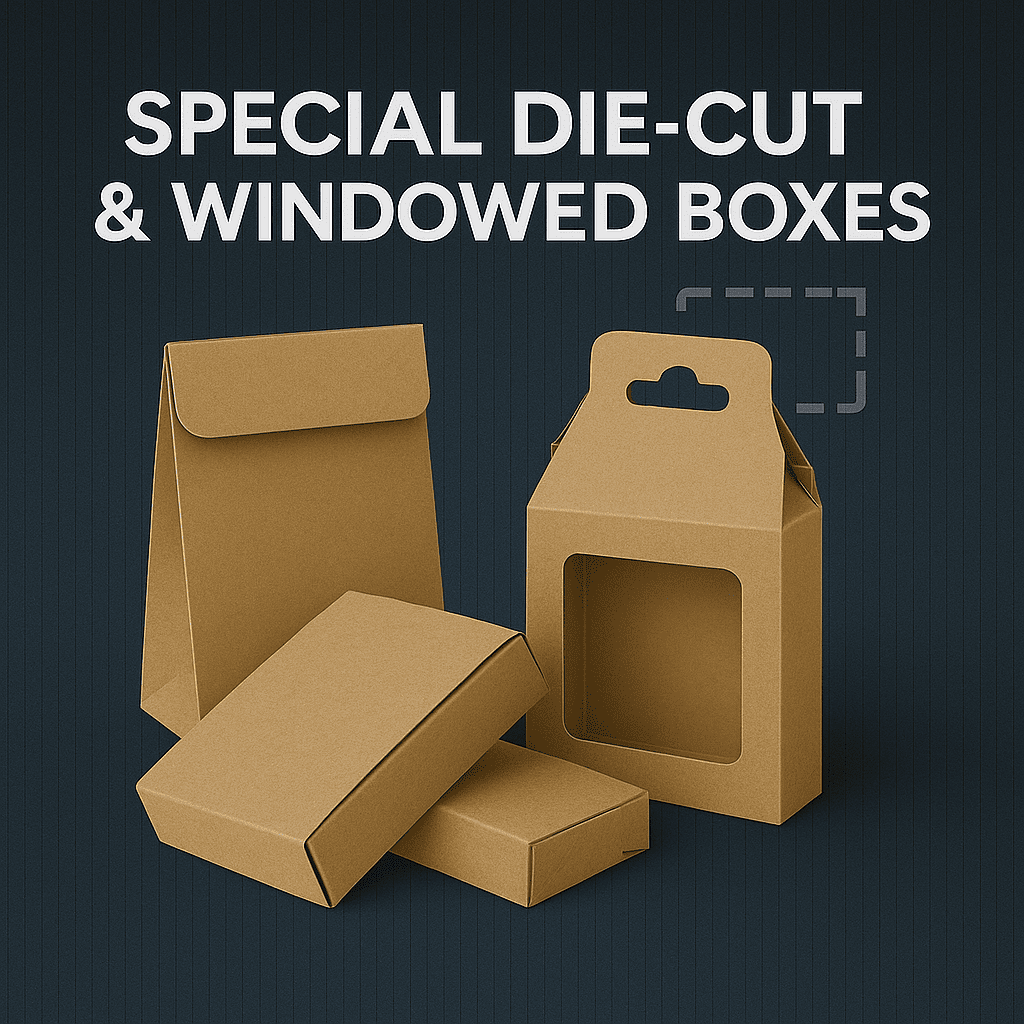

Custom Cut & Windowed Boxes

Custom Die-Cut & Windowed Boxes – Shelf Visibility and Experience

Showcase your brand in-store with die-cut custom forms, window displays, and smart closures. Achieve fast setup and high protection with options like PET/PP windows, euro hangers, handles, and auto-lock bottoms.

Shelf Visibility

Product display with a clear window

Custom Form

Die-cut, handle/euro hanger, lock variants

Fast Setup

Tuck-end & auto-lock bottom

Sustainable

100% paper-based options

Construction & Technical Options

| Structure | Material | Window | Use | Note |

|---|---|---|---|---|

| Tuck-End (TOP/BOTTOM) | Folding carton GC1/GC2/GD2 (300–450 gsm) | PET/PP 0.2–0.4 mm | Cosmetics, personal care, light items | Fast setup, print-friendly surface |

| Auto-lock Bottom (ALB) | Carton or E/F microflute laminated | Optional | Medium weight, fast packing | Bottom closes in a single motion |

| Euro Hanger / Handle | Carton + reinforcement | Optional window | Retail peg display | Hanger hole complies with EN standard |

| Mailer (Windowed) | E/B microflute | Large front area | E-commerce, gift sets | Peel & seal / tear strip option |

| Tray (Windowed Lid) | Carton or corrugated | Window on lid | Food (secondary), textile, toys | Easy display, fast filling |

* Values vary by project; finalized at quotation stage.

Window & Gluing Options

- Film: PET/PP 0.2–0.4 mm (clear) • Matte/anti-scratch option

- Application: Window gluing on cold-glue / hot-melt lines

- Edge Allowance: At least 6–8 mm bonding strip recommended

- Shapes: Circular/oval/curved; minimum R2–R3 mm on dies

- Security: Internal lock, tamper strip, and seal label area

Design Tips

- Avoid fold/score lines around the window area

- Use 3 mm bleed and guide lines on artwork

- Plan additional reinforcement for the carry handle

- Check the sequence and compatibility of post-print lamination/varnish

- Verify product seating and window alignment with a prototype

Printing & Surface

- Offset: CMYK + Pantone, fine screen detail

- Surface: Matte/Gloss/Soft-touch lamination, water-based varnish, spot UV

- Effects: Hot foil, emboss/deboss

- Color Management: Digital proof and consistency in mass production

Industry Applications

Cosmetics Personal Care Food (secondary) Toys Electronic Accessories Textile & Accessories Gifts

Sustainability

Focus on 100% paper-based packaging. Windowless alternatives or lower-gsm clear film options are available. If bio-based/biodegradable film solutions are available, indicate them here.

Quality & Testing

In-process controls and batch-level traceability. Window pull/peel and drop tests can be reported on a project basis.

Frequently Asked Questions

PET/PP film is typically used. According to local regulations, film and carton should be collected separately; windowless options are also available.

With the correct bonding strip width (min. 6–8 mm), suitable adhesive, and surface treatment, the window remains secure. Product-based prototyping and pull tests are recommended.

Generally, 6–8 mm margin and R2–R3 mm corner radius are recommended; these vary by material and format.

Choose offset for detailed visuals and a premium look; choose flexo for simpler graphics and cost advantages. For microflute constructions, offset is used as lamination.